Mobile users:

For best results, view in Landscape mode.

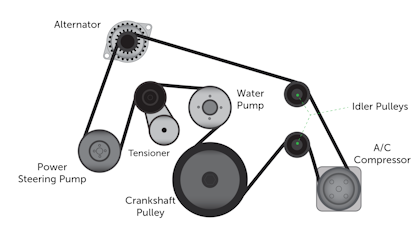

The serpentine belt, also known as the drive belt, is a belt on a

car engine that works with the idler, tensioner, and pulleys inside

the accessory drive belt system.

Most cars from 1990 and newer have serpentine belts.

The serpentine belt is located on the side of the engine and can

be inspected from under the hood.

It's a thin, rubber belt that winds around several components in

your engine, like a snake (hence 'serpentine').

The drawback of this single belt is that if the belt breaks or is knocked

loose, the vehicle instantly loses multiple critical functions.

The water pump, power steering pump, and alternator

(for battery charging) would cease functioning.

A new serpentine belt has a soft felt-like surface on the ribbed side.

As the belt wears out, the belt rubber hardens and cracks.

Pay attention to the engine’s temperature gauge.

A sign of a loose serpentine belt may be the vehicle overheating.

Avoid allowing the vehicle to overheat, as it can cause permanent

and expensive damage to the cylinder head.

Squealing noise:

If you notice a squealing noise coming from the front of your vehicle,

it could be from the serpentine belt.

When you start to notice a squealing noise, the belt looks bad, the

engine overheats, or loss of power steering, have your mechanic

check it right away.

A worn-out belt stretches and loses tension.

This causes the belt to start slipping from time to time.

It is not recommended that you drive a vehicle with a damaged,

loose, or severely worn serpentine belt.

Thoroughly inspect your serpentine belt and check for wear.

Have your mechanic inspect your serpentine belt each time you get

an oil change if you prefer not to do it yourself.

If the serpentine belt fails, it can cause damage to the engine parts,

which in turn can be an expensive headache.

Check for signs of wear.

Check the edges of the belt for wear and fraying.

Serpentine belts move at high rates of speed and can catch any loose

fitting clothing or jewelry if you get close while the engine is running.

Do not get close to the belt while the engine is running.

If the belt is showing sign of wear like polished edges, it likely will

need to be replaced.

If the serpentine belt is loose, the belt grooves may begin to melt

and glaze over.

Glazing is easy to spot, as it will look shinier than the rest of the

rubber the belt is made of.

Glazing occurs as the belt passes over pulleys without placing enough

tension on them to actually make them turn with the belt.

If the grooves of the belt have glazed over, you’ll need to replace

the belt.

Look for fraying, notches, cracking, glazing, too much slack on the belt,

uneven wear on ribs or belt, and misalignment on the pulleys.

The cracking looks a little like dry-rotted rubber.

Check the tension of the belt periodically.

If a belt starts slipping, the tensioner should also be checked to see

if it is functioning properly.

Check the tension by pushing down on the belt with your hand.

The belt should have about a half an inch of play when at the

appropriate tightness.

Grab any area of the belt that is between two pulleys with your fingers.

Most serpentine belts have an auto- tensioner that automatically keeps

the proper tension on the belt.

However, some belts have an adjustment screw that applies tension

to the belt.

If the serpentine belt is too loose, your alternator will not properly

charge your battery and your accessories may not work properly.

The required measure of tension in the serpentine belt is that it should

not deflect more than ½ inch when twisted either way from the middle.

If twisted more, the belt is loose, and if twisted less, the belt is too tight.

If your serpentine belt is installed with a self tensioner, ask your

mechanic to replace the tensioner when they replace your serpentine

belt.

Today's serpentine belts are designed to last around 100,000 miles.

But it's recommended that you replace the serpentine belt every

50,000 to 60,000 miles.